Cost Effective Vibration Test Machine Payload Up To 300kg Vertical Only

Cost Effective Vibration Test Machine Payload up to 300kg Vertical Only

Principle Introduction

Mechanical vibration test machine applies to electronic products, components, module, mechanical

and electrical products, instruments and meters and other transportation vibration simulation test. It

meets the standards of GB, UL, IEC vibration test and reliability test.

Our mechanical vibration table has three testing functions, namely vibration test under particular

frequency, frequency sweep test, and multi-stage random test. These three test functions enable

users to perform various tests on their products, such as vibration function test, vibration endurance

test, package transportation test, resonance search, resonance dwell, stress screening and fatigue

test.

Features

1, Using centrifugal excitation method, low mechanical noise.

2, Using synchronous reverse movement, excellent table evenness.

3, Stepless amplitude adjustment, meet different product test

requirements.

4, Use-friendly operation control interface.

5, Fixed with shock absorption bags without special foundation.

Specifications

| Model | RV8000 |

| Table Size(L×W) | 1000 x 800mm |

| Freq. Range(Hz) | 5--60 Hz |

| Disp. (mmp-p) | 0—2.6 p~p |

| Acc. Range | 0--11 G |

| Max. Payload(kg) | 300 kg |

| Wave Form | Sine pulse |

| Vibration Direction | Vertical |

| Power Supply | AC 220V /50Hz |

| Machine Dimension | 1000*800*655mm |

| Machine Weight | 550kg |

Precautions

1. Single phase AC 220V ±10%(50Hz) power supply is employed for the vibration tester table.

2. Adjustment of eccentric block: The eccentric blocks for the machine are of the design of four

groups (eight eccentric blocks, 2 blocks form a group). The eccentric blocks on two shafts are in

reverse and synchronous rotation. In order to make the table vibrate evenly without shaking, the

included angles of eccentric blocks must be the same and located at relative position. A group of

eccentric block can be turned to make the direction of opening towards the horizontal left, and the

other group must be in the horizontal right direction.

3. The fastening bolts of eccentric blocks must be fixed properly to avoid slipped thread by force.

4. During the adjustment of eccentric blocks, the machine must be at the stop state, and it is better to turn off the machine’s power supply (instead of the computer). The front and rear panels of the

eccentric blocks must be fixed before operation.

5. When you hear irregular noise or the machine has severe irregular shaking, it is necessary to shut

down the machine and check the machine immediately or notify the supplier.

6. All bolts on the upper part of the vibration table (above the damping spring) cannot be unfastened

counterclockwise to avoid damage of the machine.

7. The power supplies for the machine and computer shall be turned off when the vibration table is not

in use.

Detailed Picture:

Labtone Test Equipment Co., Ltd

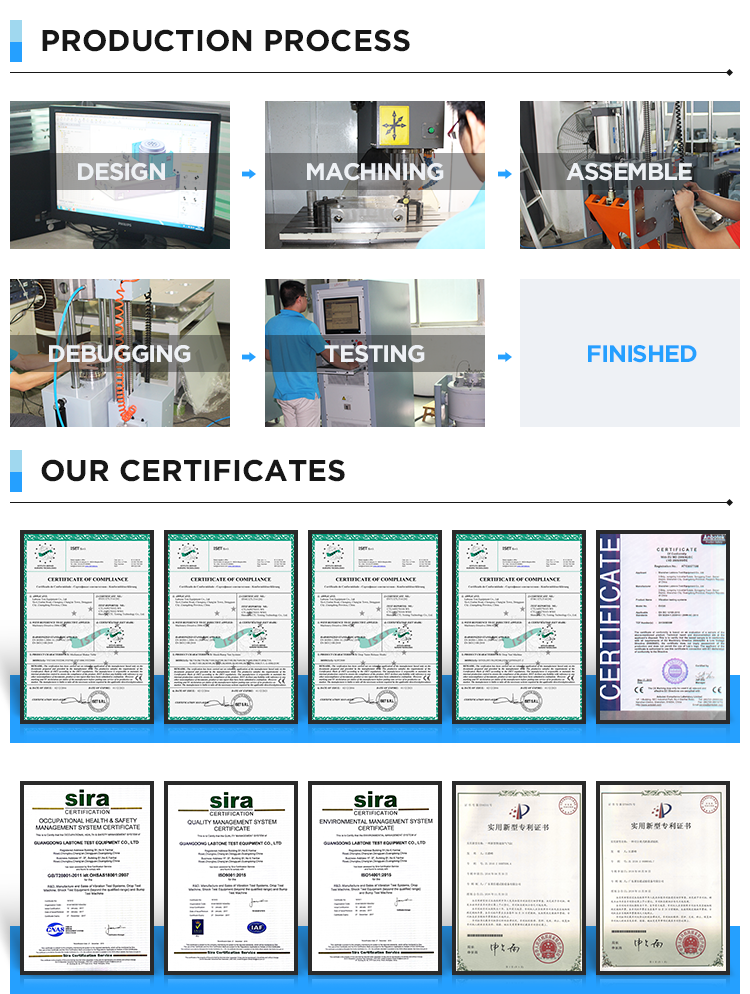

Labtone Test Equipment Co., Ltd. is a +20 year China manufacture of reliable, cost-effective equipments . Our superior products mainly include: Vibration Test Systems, Shock Test Systems, Bump Test Machine, Drop Tester, Transportation Simulators, Combined Environmental Test Chambers.

Labtone started business in 2002 in a plant located in Shenzhen and moved to our new, expand 6,000 square meter facility in Donguan, GuangDong in 2015.Today, Our products are found around the world in electronics, automotive,automotive,aerospace,telecommunication, optoeletronics instrument and industrial machinery applications. Our experience, and commitment to new product development, has resulted in products that are easy to use,accurate and designed for decades of service

Labtone products carry a one-year(12months) Warranty and are available direct from our factory in Dongguan, China. We provide comprehensive factory service and support,technical literature, manuals and guides as well as having a qualified staff of experts to help solve your application issues.

We sincerely invite you to visit our factory.